How Injection Molding Machines Work: A Complete Beginner’s Guide

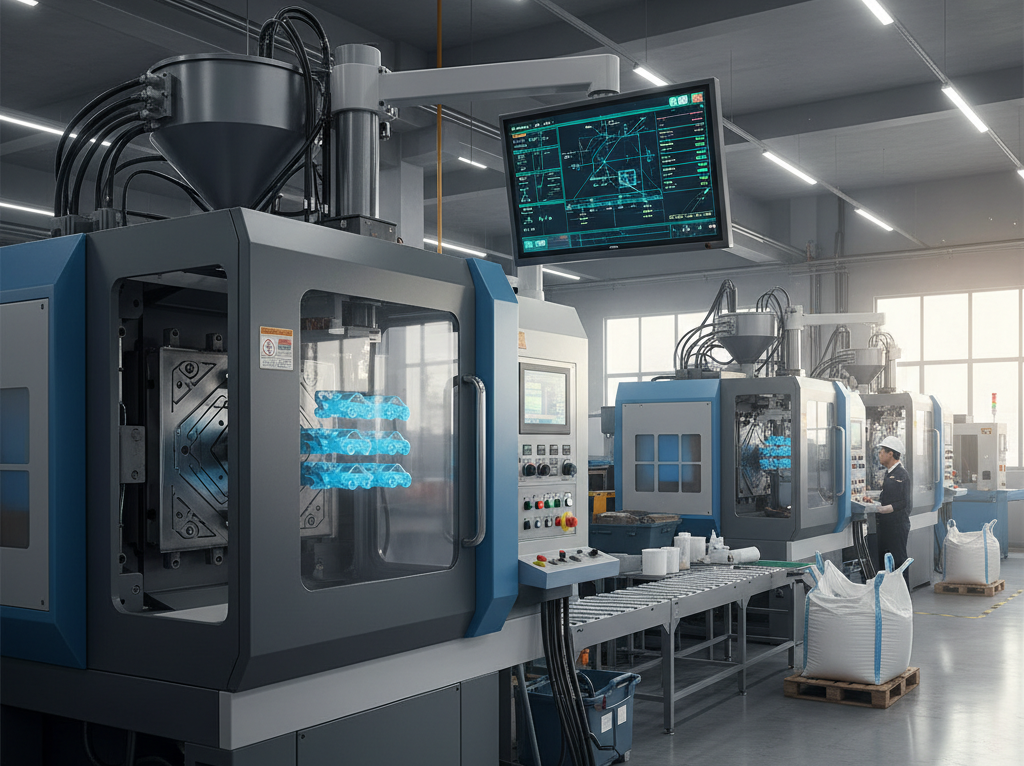

I still remember the first time I stood in front of a full-size injection molding machine. The noise of the clamping unit locking the mold, the hiss of molten plastic being forced inside, and the sudden smell of heated resin filled the air. I was fresh in the industry back then, a little nervous but mostly excited to finally see in action what I had only read about in textbooks.

The machine operator let me watch closely as the cycle repeated clamp, inject, cool, eject. Within seconds, a perfectly shaped plastic part dropped onto the conveyor. I picked one up and was amazed at how precise and consistent it was compared to handmade prototypes I had worked on before.

Over the weeks that followed, I spent long hours around those machines. I learned how even small changes in temperature or injection pressure could affect the final part. I also saw how important maintenance was—one clogged nozzle or misaligned mold could stop production for hours. That hands-on experience made me appreciate the engineering behind these machines. It was more than just pushing buttons; it was about understanding the process and respecting the delicate balance between heat, pressure, and timing. That’s why today, when I explain how injection molding machines work, I don’t just talk about theory—I share the things I learned standing right there on the factory floor.

Injection molding machines are among the most widely used equipment in modern manufacturing, responsible for producing countless plastic parts that we use every day. From packaging and household items to automotive components and medical devices, this process has become a cornerstone of industrial production. In this guide, we’ll explore how these machines work, their main components, and why they are so essential in today’s industries.

The Basic Principle of Injection Molding

The injection molding process involves melting plastic material and injecting it into a mold where it cools and solidifies into a finished part. The cycle is highly repeatable, making it ideal for mass production. Each cycle can take anywhere from a few seconds to a couple of minutes, depending on the size and complexity of the part.

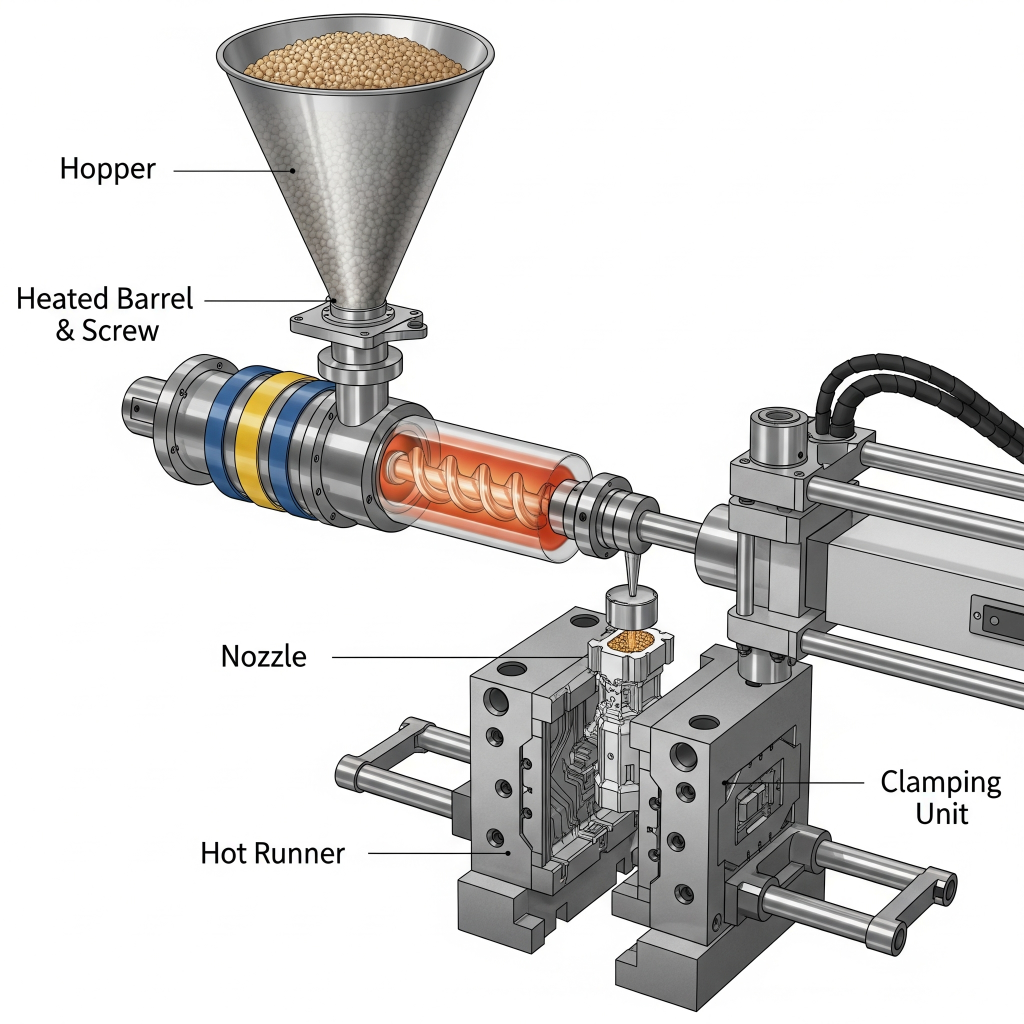

Main Components of an Injection Molding Machine

- Hopper: Holds raw plastic pellets before they enter the machine.

- Heated Barrel & Screw: The plastic is melted as it moves forward through the rotating screw.

- Nozzle: Directs molten plastic into the mold cavity.

- Mold: A custom-designed cavity where the final part is formed.

- Clamping Unit: Keeps the mold tightly closed during injection and cooling.

The Step-by-Step Process

- Clamping: The two halves of the mold are securely closed.

- Injection: Molten plastic is injected under high pressure into the mold cavity.

- Cooling: The plastic solidifies as it cools inside the mold.

- Ejection: The mold opens, and ejector pins push out the finished part.

This cycle then repeats, allowing manufacturers to produce thousands or even millions of identical parts with consistent quality.

Why Injection Molding Is So Popular

Injection molding offers unique advantages over other manufacturing methods:

- Efficiency: Capable of high-volume production at low cost per part.

- Precision: Produces complex shapes with tight tolerances.

- Material Flexibility: Works with a wide range of plastics and composites.

- Consistency: Every cycle produces parts with uniform quality.

Injection molding machines play a crucial role in shaping modern manufacturing. Understanding how they work provides insights into why this process dominates industries worldwide. For beginners, this knowledge opens the door to deeper exploration into materials, machine types, and future trends in manufacturing technology.